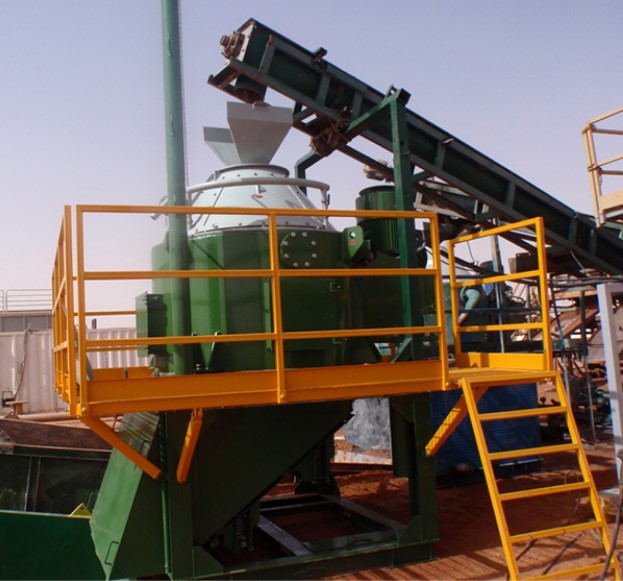

Core equipment for drilling waste management——Vertical Centrifuge

Vertical Centrige, also name vertical dryer, It can process various drilling cuttings and drilling fluids, and the processing capacity can reach 60 tons per hour. The dry solid phase oil content after spin dryer treatment is usually ≤5% (w/w).

Why need a Vertical Centrifuge?

Due to increasingly stringent environmental protection regulations, oil and gas field operators and drilling contractors are under pressure to reduce the discharge of drilling waste and change the original drilling mud and drilling waste treatment process. At the same time, changes in oil prices have also made it increasingly important to recover and recycle water, diesel oil and other valuable mud materials through scientific and reasonable drilling waste treatment processes to save drilling costs.

In offshore and onshore drilling projects, the use of vertical dryers can well meet the needs of drilling mud and drilling wastes that do not land on the ground. Untreated drilling mud and drilling waste resulting from drilling waste, rig site moves and historical backlogs.

Vertical cuttings dryer can effectively handle water-based, oil-based and synthetic-based drilling fluids, and produce extremely dry cuttings, reduce cuttings discharge, recover a large amount of drilling fluid, reduce drilling costs, and at the same time Also protect the environment.

Features and Benefits:

Environmental protection and saving

-

Efficient solid-liquid separation to minimize the liquid content of drill cuttings.

-

Reduce the amount of drilling waste disposed of.

-

Effective separation can recover a large amount of drilling fluid for reuse in circulating mud system.

-

Cost-effective recovery of all mud lost to shaker failures, rig movement and screen blockages.

Operational advantage

-

Programmable Logic Controller (PLC) with automatic alarm indicators to monitor temperature, torque, oil quantity and run time.

-

Large-capacity continuous feeding device, so that its processing capacity can fully meet the needs of drilling.

-

Tungsten carbide coating and independently adjustable vanes reduce wear and ensure optimum performance.

-

Handrails and walkways facilitate routine operator maintenance and reduce personnel risk.

-

Screens of different specifications meet the needs of customers in different working conditions.

Easy to maintain

-

Easy access from the top of the unit for easy replacement of normally worn parts. Belts can be easily replaced without removing the gear assembly.

-

Interchangeable tungsten carbide blades protect the rotor and gearbox from excessive corrosion and minimize the failure rate of major components.

-

Explosion-proof motors and control panels are CE/ATEX certified.