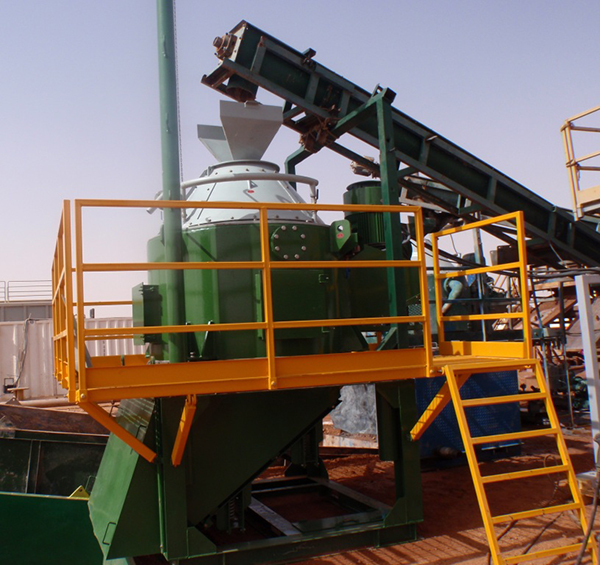

Vertical Centrifuge

VC-1000 series vertical cuttings dryer (vertical centrifuge) produced by GREEN is a type of vertical centrifuge which can perform solid/liquid separation through centrifugal separation. The vertical cuttings dryer can effectively recover the liquid p

Online Inquiry

Consultation E-mail: sales@green-sep.com

VC-1000 series vertical cuttings dryer (vertical centrifuge) produced by GREEN is a type of vertical centrifuge, which can perform solid/liquid separation through centrifugal separation. The vertical cuttings dryer can effectively recover the liquid phase in drilling cuttings, making the solid phase become very dry. It is suitable for water-base mud, oil-base mud and synthetic base mud. By recovering the mud in drilling cuttings, the vertical cuttings dryer can reduce the drilling cost and cut down environmental pollution. With handling capacity of 40-60 T/h, the oil on cuttings (OOC) of drilling cuttings can be reduced to lower than 5% (w/w) after treatment, meeting the international emissions standards and environmental protection requirements. The vertical cuttings dryer can also be applicable for drilling waste management in onshore and offshore drilling.

Features and Benefits:

Environmental and cost

• Highly effective liquids/solids separation minimizes fluid content of cuttings

• Reduces waste-disposal volumes

• Effective separation reclaims high percentages of fluid that can be reused in the active mud system

• Recovers whole mud lost from shale shaker failure, rig motion and screen blinding, that is cost- effective.

Operational Advantages

• Programmable Logic Controller (PLC), with automatic warning indicators, monitors temperature, torque, oil flow and operating hours

• High-capacity, continuous feed units have the throughput to keep up with drilling

• Tungsten-carbide-coated, independently adjustable flights reduce wear and ensure optimal tolerance

• Handrail and walkways is convenient for operators to do routine maintenance work, that can reduce risk to personnel

Different kinds of screens can meet various operation requirements

Ease of Maintenance

• Normal wear parts are easily accessible from the top of the unit; belts are easily

• changed without removing gear assembly

• Interchangeable tungsten carbide flights protect rotor and gear box from excessive erosion, minimizing main component failure

• Explosion-proof motors and control panels can be certified with CE/ATEX

A professional supplier which specialized in solid-liquid separation equipment in the energy industry, mainly supply drilling shale shaker, decanter centrifuge, mud cleaner, desander and desilter, mud agitator, vacuum degasser, shaker screen, cyclones, slurry pump and solid control equipments spare parts products etc.

Vertical centrifuge specification parameters

Vertical centrifuge specification parameters

| VC岩屑甩干机 Vertical centrifuge | ||

|---|---|---|

| 型号 Model | VC800 | VC1000 |

| 筛网最大直径 Max. Daimeter of screen | 750mm | 950mm |

| 主电机功率 Main motor power | 37kw | 55kw |

| 油泵电机 Oil pump motor | 120W (0.16HP) | 120W (0.16HP) |

| 处理量 Treating Capacity | 25~40T/h | 40~60T/h |

| 处理后含油率 Oil on cuttings | ≤5% | |

| 筛网规格 Screen opening |

0.20mm/0.25mm 0.38mm/0.51mm |

0.38mm/0.51mm |

| 外形尺寸Dimensions(L×W×H) | 2300×1600×1800mm | 3820×3360×5900mm |

| 重量 Weight | 3200kg | 6000kg |

| 电制 Power | 380V/50Hz标配,其他选配 | |

on-lineMessage ordering

Recommended products

Information Center

- Advantages of Decanter Centrifuges 2022-10-31

- Slurry Solidification Equipment and Slurry Solidifi 2022-10-31

- GREEN Hot Well Mud Solids Control System 2022-10-30

- How to deal with shield muck in subway construction 2022-10-30

- Mud non-drop system manufacturer, drilling waste tr 2022-10-30

- The role of mud-water separation equipment in the c 2022-10-30

- GREEN's vertical centrifuge introduction 2022-10-30

- Shield Mud Treatment System 2022-10-30

- Vibrating screen production workshop 2022-10-28

- The role of mud Agitator in mud purification treatm 2022-10-28

Green Environmental Co., Ltd.

A professional supplier which specialized in solid-liquid separation equipment in the energy industry, mainly supply drilling shale shaker, decanter centrifuge, mud cleaner, desander and desilter, mud agitator, vacuum degasser, shaker screen, cyclones, slurry pump and solid control equipment spare parts products etc.

Online consultation

Consultation telephone 86-29-81129488 sales@green-sep.com