in oil and gas drilling and urban foundation engineering construction, as well as the remaining mud after completion of wells, need to be treated to ensure environmental safety. There are generally two types of waste pulp treatment methods: chemical (flocculation, solidification) and mechanical (sand removal, cleaning and transportation). However, the mechanical method is most used in the oil drilling process, that is, the mud does not fall into the system to dispose of the waste drilling fluid.

An important link in waste slurry treatment can reduce the oil content of solid particles larger than 0.5mm in waste slurry to below 5%, and the water content to below 15%. The mud non-falling system can effectively control the water content (6%-15%) and oil content (2%-8%) of drilling cuttings in the drilling mud, stabilize the liquid phase performance, and achieve the purpose of drying the mud without falling to the ground.

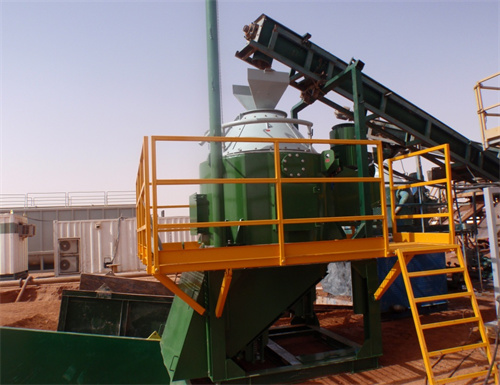

Generally speaking, most of the mud do not fall to the ground are composed of mud shale shakers, dryers, centrifuges and other equipment that do not fall to the ground. Kesheng Energy has three configuration schemes for the mud non-falling system:

plan 1

The system consists of a vibrating screen, a centrifuge and a tank, and is mainly used for the treatment of waste slurry and tailings of drilling water-based mud. Advantages: After treatment, the mud can be recycled and reused. Disadvantages: After treatment, the solid phase has a large water content.

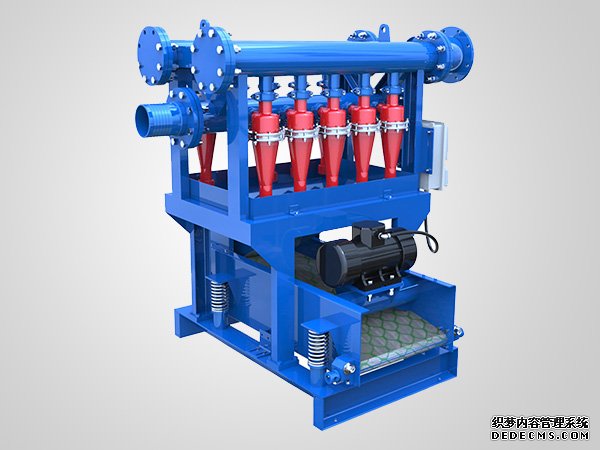

Scenario 2

The system is mainly composed of a dryer, a centrifuge and a tank, and is mainly used in the treatment of various drilling oil-based mud, water-based mud and tailings. After the treatment, the solid phase contains little oil and water.

Scenario 3

The system consists of a filter press, a dosing device and a tank, and is used in the treatment of various drilling water-based mud and tailings. Advantages: low moisture content in the solid phase after treatment, disadvantages: complex process and large floor space

Our company is committed to the development of environmentally friendly

mud non-drop treatment technology, and has rich experience and brand effect in the industry. Welcome to consult our company.