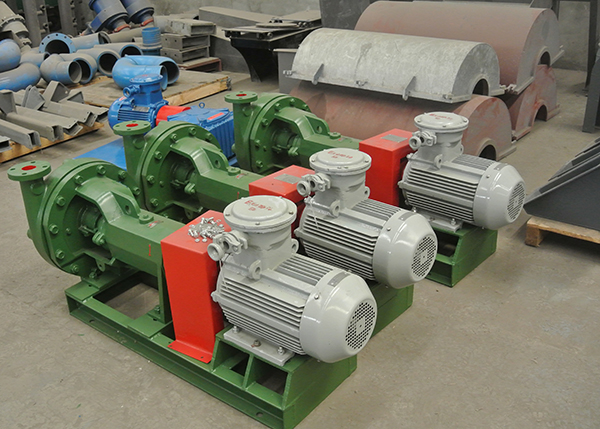

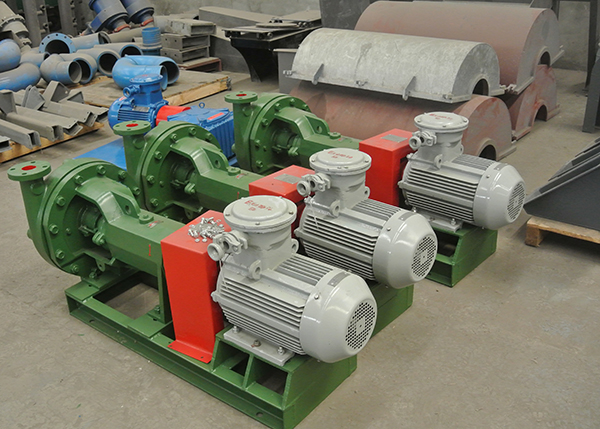

Bentonite mud sand pump

Bentonite sand pump introduction:

GREEN Bentonite mud sand pump are mainly used for transporting drilling fluid mud, as well as for desander, desliter, slurry supply pumps for centrifuges, as slurry mixing pumps for jet mixing, and as filling pumps for recharge and mud pumps. all models of GREEN sand pumps use mechanical seals for long life and reliable performance. All parts are interchangeable with pumps of international famous brands, thus making it easier for users to find wearable parts for replacement.

Bentonite mud sand pump Advantages & Features:

1.All parts are interchangeable with international well-known common brands, reducing the user's parts inventory and lowering parts procurement costs.

2.The centrifugal pump casing adopts coaxial thickening design, which reduces the vibration and wear during pump operation and prolongs the service life of the casing.

3.The mud centrifugal pump casing is made of precision casting of wear-resistant alloy ductile iron, which is more wear-resistant than ordinary material pump casing.

4.The open impeller design effectively reduces the bearing capacity of the shaft and bearings and prolongs the service life of the bearings.

5.The impeller is made of wear-resistant alloy ductile iron precision casting, which has a longer service life than impellers made of ordinary materials.

6.The impeller adopts anti-loosening design to prevent the Slurry Bentonite Pump from being damaged when reversing outside.

7.High quality mechanical seal is adopted to prevent the sand pump from leaking and reduce the maintenance time of the drilling mud centrifugal pump.

8.Replaceable shaft sleeve to prevent shaft wear.

9.The bearing adopts international famous brand bearing, which has stable operation and long service life.

10.The base of the sand pump adopts integral casting base instead of the welded base of the counterparts, which makes the operation more stable and prolongs the service life of the whole pumps for drilling mud.

X

Whatsapp/Wechat:

Jean Li

+86 152 4926 4410

Moria Guo

+86 159 0297 1861

已复制,打开APP添加!